Philippines

Philippines

- 0966-200-2764

- 0917-850-0777

- 0945-711-2322

- (02)8461-7187

- [email protected]

- fb.com/7TMWinc

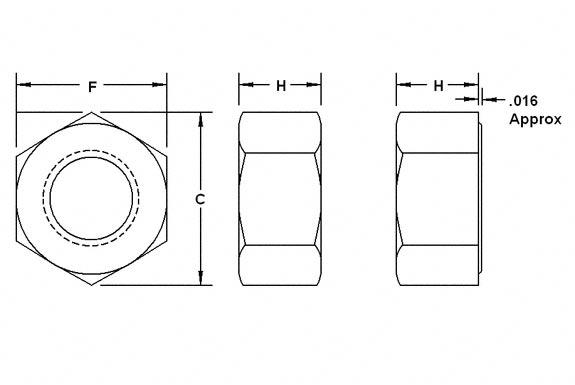

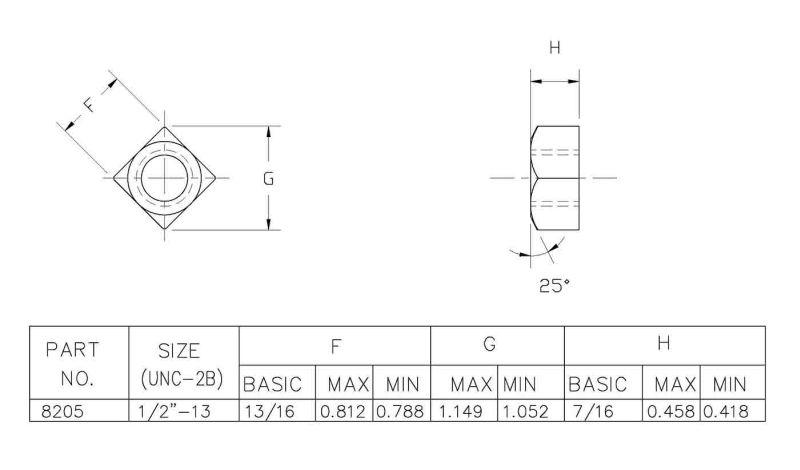

A Zinc-Plated Hex Nut is a type of fastener that is widely used in various industries for securing objects together. It is made of steel and has six sides, which allow for a wrench or pliers to easily grip and turn the nut. The hex shape is advantageous because it provides a greater surface area for gripping and tightening than other shapes like square or round nuts.

The process of zinc plating involves coating the surface of the steel with a layer of zinc. Zinc is a popular choice for plating steel because it is a sacrificial metal, which means that it corrodes before the steel. This provides a protective layer for the steel, preventing rust and corrosion from damaging the fastener.

Zinc-plated hex nuts are commonly used in automotive and construction applications, as well as in manufacturing and industrial settings where corrosion resistance is important. Zinc plating provides an inexpensive and effective way to protect the nuts from the elements and prolong their lifespan.

It is important to note that while zinc plating provides a significant level of protection against corrosion, it is not a permanent solution. Over time, the zinc layer may wear away, exposing the steel to moisture and oxygen, which can cause rust and corrosion. To ensure the longevity of zinc-plated hex nuts, it is recommended to use them in applications where they are not constantly exposed to moisture or harsh chemicals. Additionally, periodic inspection and maintenance can help detect and prevent corrosion issues before they become more severe.