Philippines

Philippines

- 0966-200-2764

- 0917-850-0777

- 0945-711-2322

- (02)8461-7187

- [email protected]

- fb.com/7TMWinc

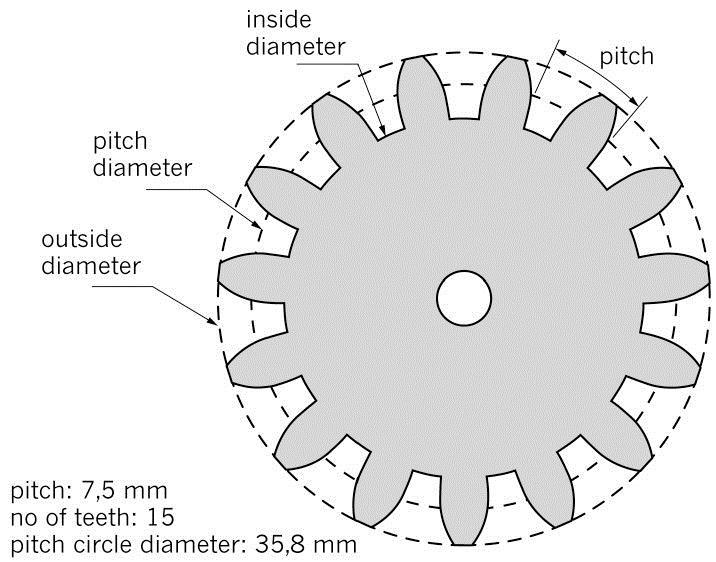

Spur Gears are cylindrical gears with teeth that are straight and parallel to the gear's axis, setting them apart as a widely employed gear type in numerous industries. Their straightforward design and exceptional versatility make them indispensable components in automotive, machinery, robotics, and power transmission systems.

These gears feature a distinct tooth profile characterized by straight, parallel teeth running across the gear's surface. This design ensures efficient and effective power transmission between parallel shafts, allowing for a smooth and reliable transfer of rotational motion.

One of the notable advantages of spur gears is their ability to achieve high gear ratios, determined by the ratio of teeth between the driving and driven gears. This flexibility in gear ratios enables spur gears to cater to a wide range of speed and torque requirements in various applications.

Spur gears excel in terms of efficiency, boasting impressive power transmission capabilities with minimal energy loss. The line contact between teeth contributes to their exceptional efficiency, ensuring optimal performance and reduced power wastage during operation.

While spur gears offer remarkable functionality, they can produce some noise and vibration due to the direct tooth-to-tooth contact. However, through careful design considerations, such as optimizing tooth profiles and implementing proper lubrication, these potential drawbacks can be mitigated, resulting in quieter and smoother gear operation.

With their compact design, spur gears are valued for their ability to optimize space utilization within gearboxes and drivetrains. They can be manufactured using a variety of materials, including steel, cast iron, brass, and plastic, making them adaptable to diverse application requirements and environments.

Spur gears find widespread use in power transmission systems, enabling the seamless transfer of rotational motion and torque between parallel shafts. They are prominently utilized in automotive transmissions, differential systems, engine timing mechanisms, and a vast array of machinery and robotic systems.

Furthermore, spur gears play vital roles in industrial equipment, such as conveyors, pumps, mixers, and printing presses. They also have a place in the world of timekeeping devices, featuring prominently in clocks and watches, where precision and reliability are paramount.

While spur gears possess numerous advantages, it's worth noting that they have limitations in handling large torque loads or transmitting motion between non-parallel shafts. In such scenarios, alternative gear types, like helical gears or bevel gears, may be more suitable for fulfilling specific requirements.