Philippines

Philippines

- 0966-200-2764

- 0917-850-0777

- 0945-711-2322

- (02)8461-7187

- [email protected]

- fb.com/7TMWinc

Anchor bolts are used to connect structural and non-structural elements to the concrete. The connection is made by an assembling of different components such as: anchor bolts (also named fasteners), steel plates , stiffners. Anchor bolts transfer different types of load: tension forces and shear forces.A connection between structural elements can be represented by steel column attacched to reinforced concrete foundation. Whereas, a common case of non-structural element attached to a structural one is represented by the connection between a facade system and a reinforced concrete wall.

Stainless steel anchor bolts are widely utilized as fasteners in construction and engineering projects due to their high strength and excellent resistance to corrosion, making them ideal for harsh outdoor environments.

One of the primary advantages of utilizing stainless steel anchor bolts is their ability to resist corrosion, thanks to the addition of chromium in their composition that forms a protective oxide layer on their surface. This feature is particularly useful in environments exposed to moisture, saltwater, and other corrosive elements.

Furthermore, stainless steel anchor bolts are also known for their durability and strength, allowing them to withstand high loads and stresses, making them suitable for demanding construction and engineering applications. They are also resistant to mechanical damage, bending, and deformation, ensuring their long-term reliability.

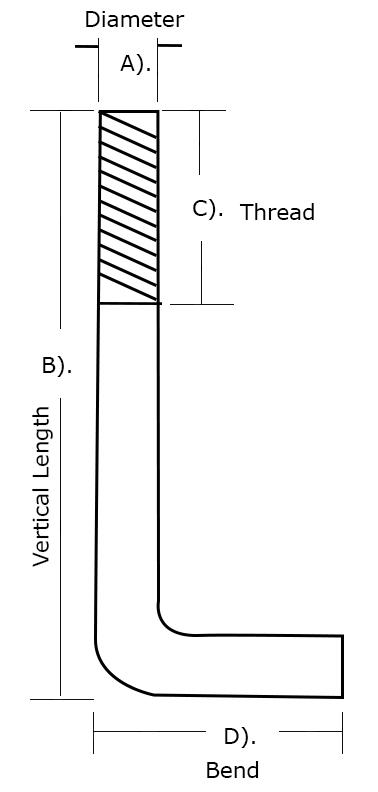

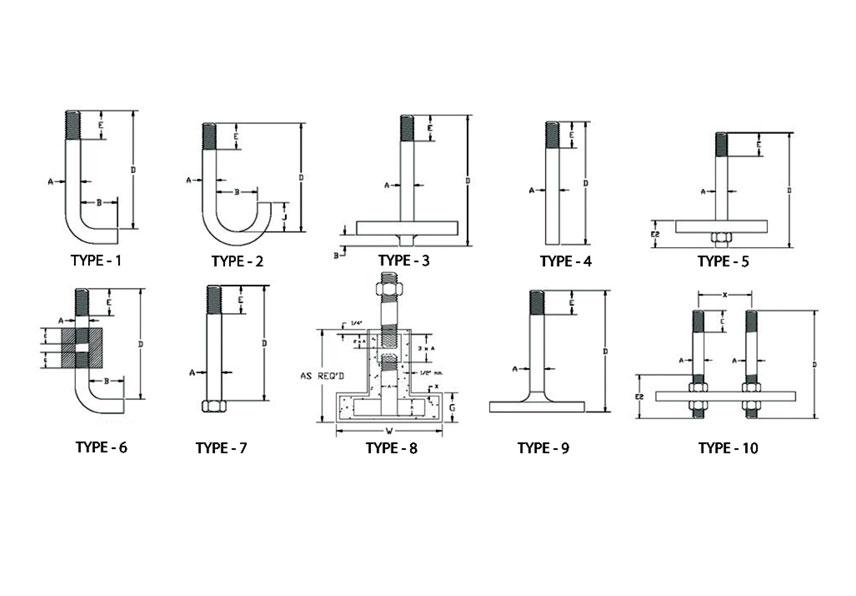

There are different sizes and configurations of stainless steel anchor bolts available in the market, allowing them to cater to various project requirements. The installation techniques used for stainless steel anchor bolts include drilling, epoxy anchoring, and mechanical expansion anchors, depending on the project's specific needs.

In summary, stainless steel anchor bolts are a dependable and long-lasting fastener solution that provides high strength and corrosion resistance, making them suitable for use in harsh outdoor environments. Their durability and minimal maintenance requirements make them a reliable solution for construction and engineering projects that require high-performance fasteners.